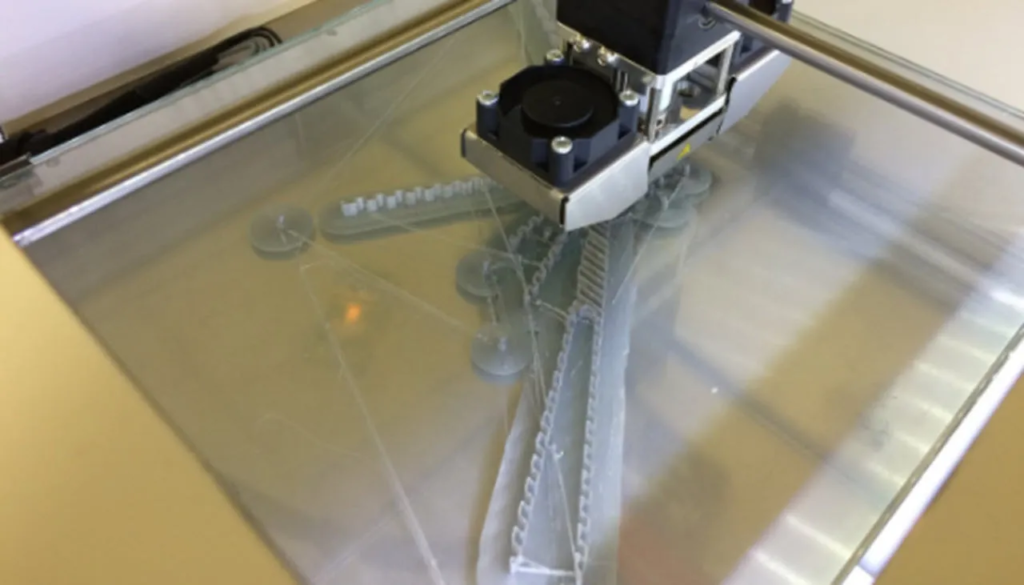

3D printing was a fancy term in 2013, and I first overheard that IIT Bombay Computer Science Department is getting one of the first 3D printers in India. And I was amazed at it. I was amazed at the thought that printing will be happening across three axes (X, Y, and Z too) and that was something my mind couldn’t imagine. How is it possible?. Obviously, printing on paper (X and Y) is not a new thing, but printing across depth (Z axis) was the real deal. The first thing I printed when I could lay my hands on that printer was a miniature Taj-Mahal (shown below), and the details were amazing. The white thread which is rolled on the left side is the raw-material.

The essential logic of a 3D printer is to build material layer upon layer. It constructs a physical object from a computer model by adding liquid layer by layer which will be solidified at room-temperature. The raw-material to it won’t be in a liquid format, it will be in a solid glue balls or glue thread format (left side in the picture above). This when exposed to heat/air will become semi-liquid that will be deposited layer by layer.

3D Printing essentially operates on the three X, Y, and Z-axes:

- The X-axis is the left-to-right movement.

- The Y-axis is the front-to-back movement.

- The Z-axis is the upward and downward movement.

Invention of 3D Pen

During the same time, around 2012-2013, is when even 3D Pen was invented and it has a similar technology. A molten plastic (in the form of a glue thread) will be heated and made into a liquidy substance that then can be added layer by layer and build things. The idea and motivation of the inventors was to design a 3D printing device that wouldnít require any computers, software or technical know-how and would produce free hand drawn 3D objects.

Mechanisms of 3D Printing

The 3D printer has a component called Extruder. This mechanism ejects out a semi-liquid or liquid material that is used to be deposited successively to build a solid material. The liquidy material becomes solid at room-temperature, think of it like cement or gum or ink. In this way, the 3D printer extruders are very similar to the 2D paper inkjet printers.

It is a very similar technology to how even polyester is made and how polyester fabric is made. Polyester is made from PVC balls which are then heated and made into a thin line of liquid thread which gets solidified at room temperature.

Printing in 3D was a definite wonder in those days. You input the design in a particular format from the CAD software or other 3D design software and provide the necessary materials, and voila – the printing will start.

The main problems encountered with 3D printer extruders are the same as with inkjet printers, which is poor maintenance or the use of the wrong materials leading to deterioration or fouling the nozzle that projects the material.

3D Printing allowed fast prototyping

Any company wants to launch more of its products fast in this world. For example, if there is a furniture company that wants to reduce its launch time to market, then it has to prototype or build sample products really fast.

One of the most significant advantages of 3D printing in rapid prototyping is its ease of use and speed. It is a low-cost and quick method that may be utilised to make parts fast. Stereolithography (SLA) and Fused Deposition Modeling (FDM) are two methods of 3D printing. Each kind creates a tangible item in a different way, but they all produce pieces with a high level of precision and detail.

- Stereolithography (SLA): SLA printing is a procedure in which a 3D printer employs a laser to cure a photopolymer resin, layer by layer, to create a tangible item. This procedure takes time and might be tiresome. Before it can be utilised, SLA printing requires alcohol washes, UV curing, and other post-printing processes.

- Fused Deposition Modeling (FDM): A method in which a 3D printer melts and extrudes a thermoplastic material, layer by layer, to create a tangible item. FDM printing is quicker, however the quality may be poorer than SLA printing.

Hope this is useful to get a glimpse of 3D printing, thank you.

You may like to read: Binary Tree vs. Binary Search Tree vs. B Tree vs. B+ Tree, Artificial Intelligence Course for Kids, & Can you store a 13 digit number in an integer variable?